how to replace oil seal in hydraulic hose crimping machine

Classify of hydraulic hose crimping machine

November 20, 2019how to replace oil seal in hydraulic hose crimping machine

hydraulic hose crimper for sale

After long time usage and crimping and retraction movement, the oi seal in hydraulic hose crimper will have aging and wearing problem,that will result in oil leak.

At that time, the oil seal need to be replaced and today we would like to show our customers and distributors how to replace the oil seal by yourself or your engineers.

NOTICE: CUT OFF THE POWER SUPPLY, AND IT IS THE FIRST STEP BEFORE YOUR REPLACEMENT.

1.Disassemble the micrometer dial on the crimper with a screwdriver.

2.Disassemble the Rexroth magnetic valveunder the crimper head, and take it out carefully and slowly.

3.You could find there are 12 pcs hexagon screw on the crimping machine front plate, use a screw wrench to disassemble all of 12 pcs screw.

4.Take off the front cover plate of crimper head carefully and slowly.

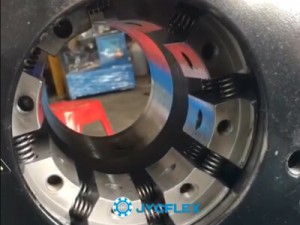

5.You could see there are 8 parts of dies base in the crimper. And connected with spring. Disassemble the die basecarefully and slowly.

6.And then move to the back of the crimper, you could see there are eight screw on the back and use your wrench to disassemble all the screw off.

7.Then take off the back of crimper head very carefully and slowly.

8.At that moment,you could see the cylinder and use a hammer or a similar tool to beat carefully and slowly.

9.Disassemble the back plate of the head, notice the screws is connected with the oil cylinder, so the screw holes of the plate should be aligned with the oil cylinder when you put the oil cylinder back.

10.Knock out of the oil cylinder from the head, check if is there any scratch in the surface of the machine head or the cylinder, if yes, please use the abrasive paper to polish the surface.

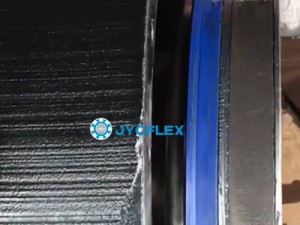

11.Replace the oil seal,two oil seal, front and back

12.Put the oil cylinder back

13.Notice the oil seal may be squeezed or crimped when the cylinder go back, you should use the oil seal screw drive to adjust the oil seal.

14.Use some long screws, it is used for align the screw holes in oil cylinder and back plate.

15.You could turn the long screw to make the oil cylinder into the machine head.Or turn on the machine, press the retraction button, please take care the process.

16.Assemble the die base and front cover.Use the long screw will help you to assemble them easily.

17.Assemble the magnetic valve and dial.

At this moment, congratulations that you have finished replacing the oil seal and the hydraulic hose crimper could work for you again.

If you have any question or still in confusion,please kindly contact us and we could send you the video.